How to Solve Common Mechanical Issues in High-Speed Siomai Makers Without Halting Production?

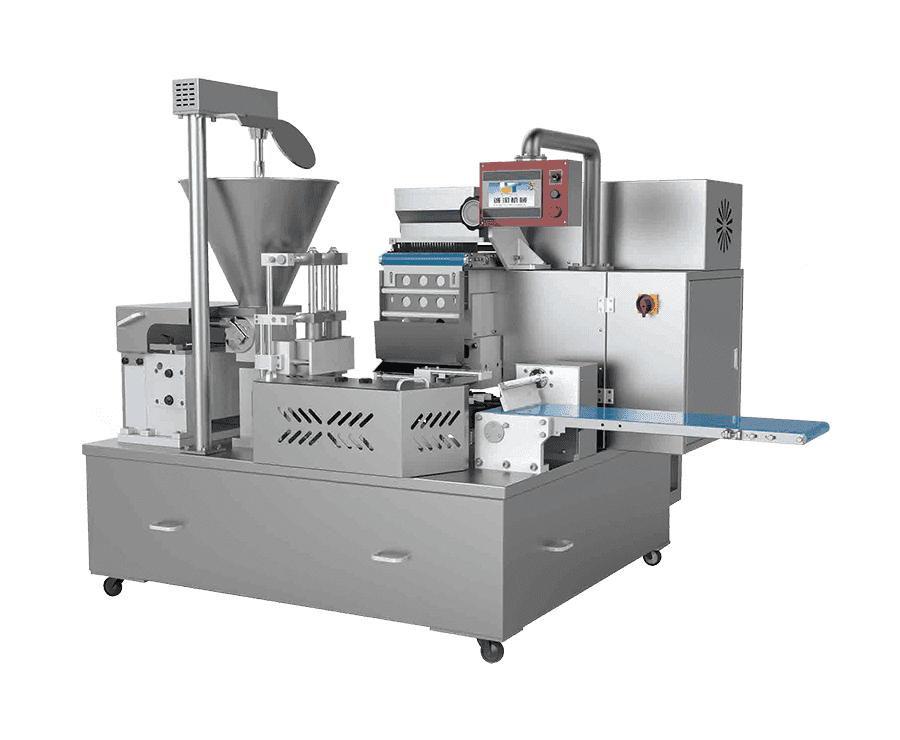

High-speed siomai makers are invaluable tools in modern food production, but like all industrial equipment, they’re not immune to mechanical hiccups. When machines are expected to produce thousands of dumplings or siomai per hour, even a minor technical issue can snowball into significant downtime and product inconsistency. In our experience as a long-standing manufacturer of automated dumpling and siomai-making solutions, we’ve seen a few key issues arise consistently across production lines—and we’ve developed targeted strategies to tackle them efficiently.

One of the most frequent challenges operators face is inconsistent filling, which often stems from wear in the quantitative filling control system. Over time, especially in high-volume environments, the precision of filling dispensers can drift if not calibrated regularly. To avoid this, manufacturers should schedule routine checks of the filling mechanism’s output levels. Our siomai maker design allows easy adjustment of filling weight, which not only improves accuracy but also prevents waste and uneven product shapes that might fail quality checks.

Another common problem is the tearing or improper alignment of the pastry skin, which is typically caused by irregular tension in the skin conveyor or inconsistencies in the dough thickness. A robust siomai making machine should include separate control systems for filling and pastry handling—this separation helps operators fine-tune each component individually without affecting the other. Machines that adopt an independent frequency conversion motor for pastry transport offer a much more stable and user-friendly approach to adjusting skin thickness on the fly, a feature that’s become a must-have for modern food production facilities.

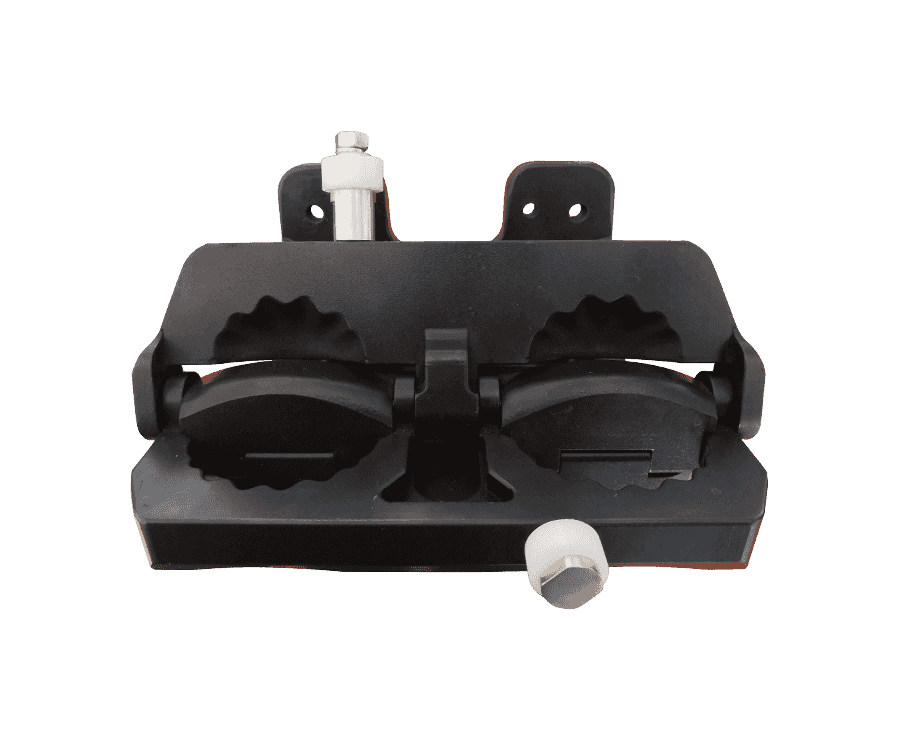

Jamming within the forming mold or filling nozzle is also a regular concern, especially when switching between different filling types or working with stickier ingredients. This issue is often preventable through proper cleaning protocols and regular maintenance. For example, the siomai maker models we produce are designed with quick-release components that allow the operator to disassemble and reassemble key parts without tools. This means cleaning can be done quickly during shift changes, reducing the risk of clogs and minimizing downtime—something every production manager can appreciate.

Unexpected shutdowns caused by electrical or sensor failures are another frustration, but these can often be mitigated through preventive diagnostics. Many modern siomai makers come equipped with real-time monitoring systems or programmable logic controllers (PLCs) that detect irregularities early. While not every customer requires advanced smart tech, even mid-range models can benefit from integrated safety interlocks and status indicators. Understanding what each signal means can help operators resolve issues on the spot without calling in a technician.

One often overlooked cause of repeated mechanical issues is operator error stemming from inadequate training or a confusing machine interface. A siomai maker with a clearly labeled control panel and intuitive operation logic drastically reduces misuse. We’ve learned that well-designed interfaces and comprehensive training materials—especially visual guides—can cut first-month service calls by more than half. When the user experience is built into the engineering, you empower the operator and protect the machine.

All these examples underscore the importance of thoughtful machine design and preventive maintenance in ensuring consistent performance. When you invest in a siomai making machine, you're not just buying a piece of hardware—you're partnering with technology that must work in harmony with your production environment, workforce, and business goals. That’s why we continue to refine every model we manufacture to solve real-world production issues, based on the feedback and needs of our global clients.

In the long run, a well-built, operator-friendly siomai maker isn’t just a tool—it’s a productivity partner that saves time, reduces waste, and maintains consistent output quality. As your operation scales or diversifies, choosing a machine that handles mechanical challenges with resilience and ease can make a measurable difference. After all, performance under pressure is what defines a reliable production solution

English

English Español

Español Français

Français русский

русский عربى

عربى

Contact Us