Three-stage progressive thinning method is adopted to press the skin into proper thickness

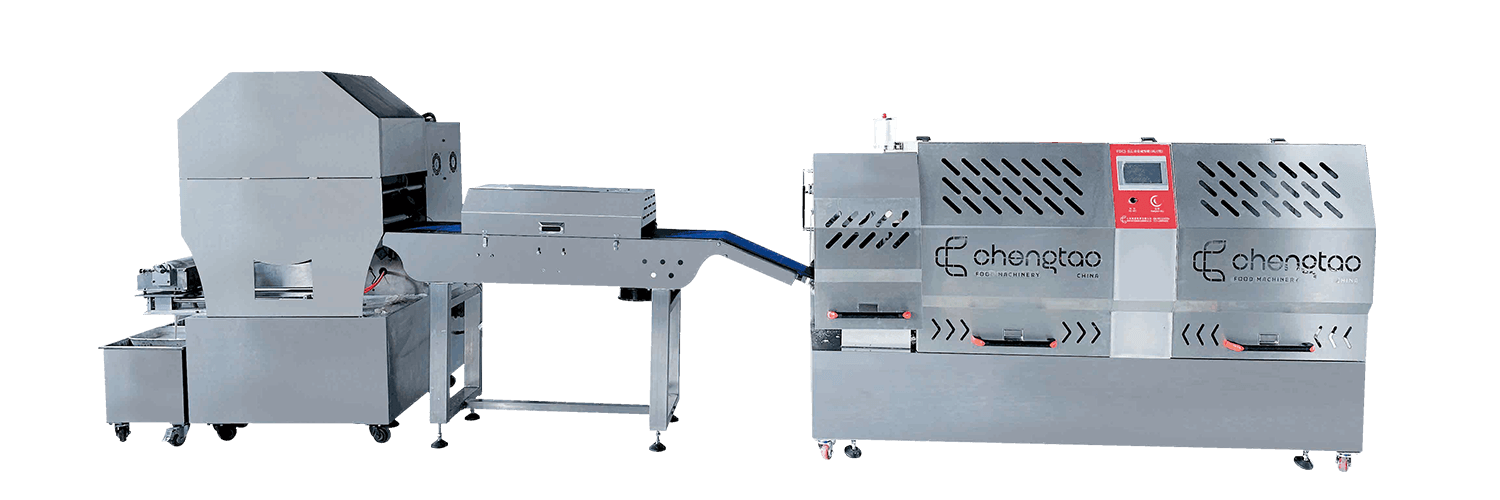

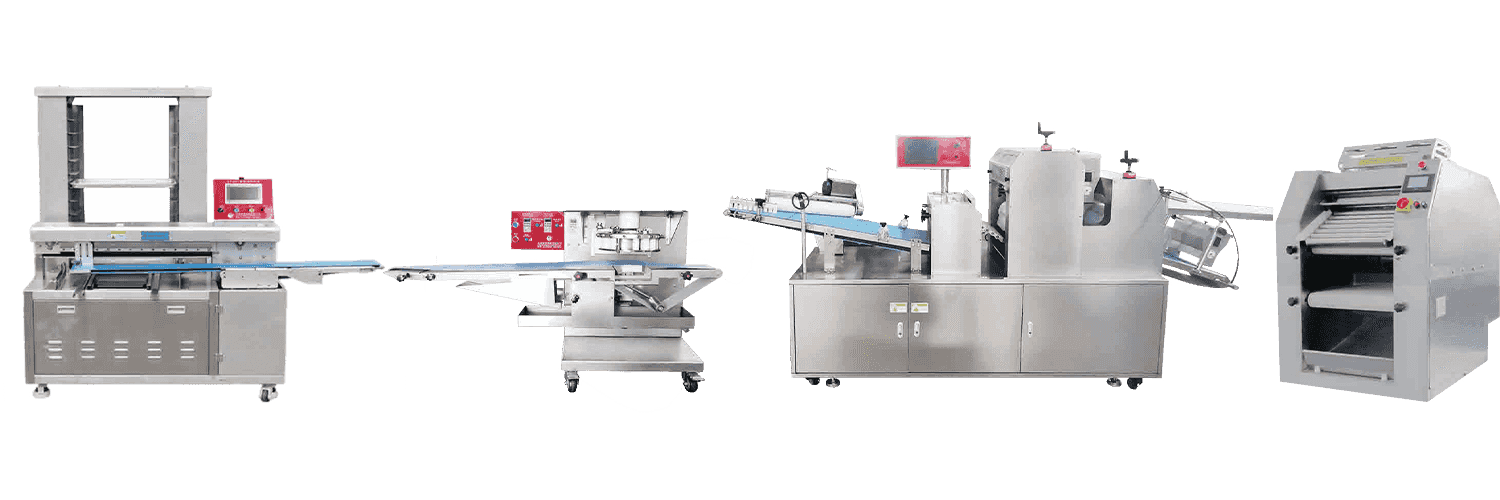

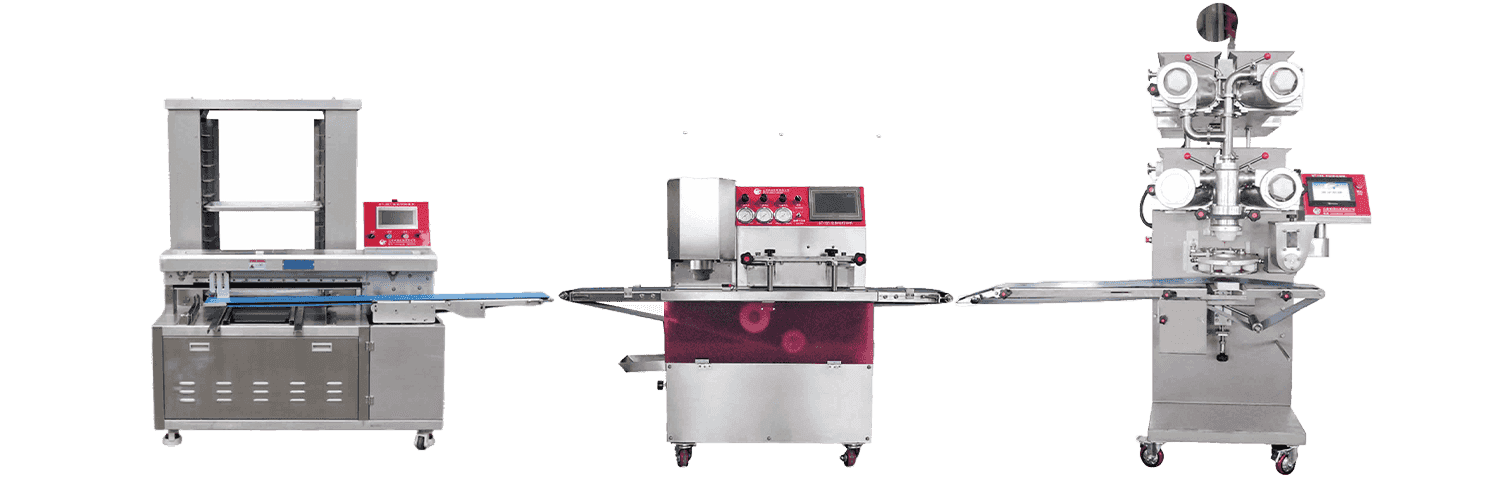

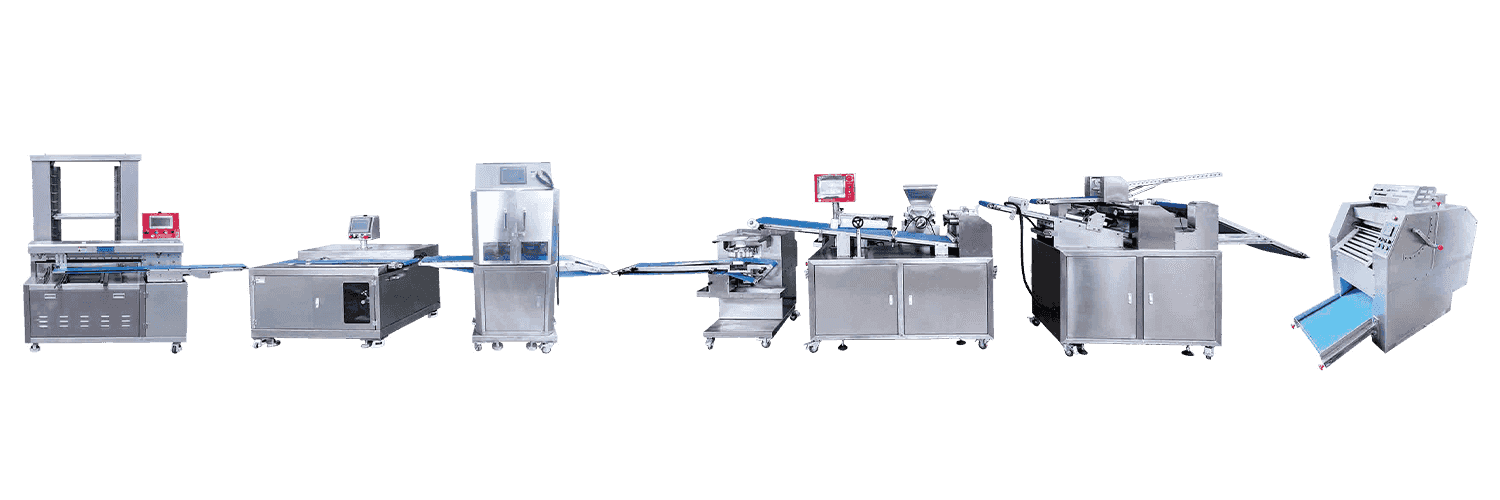

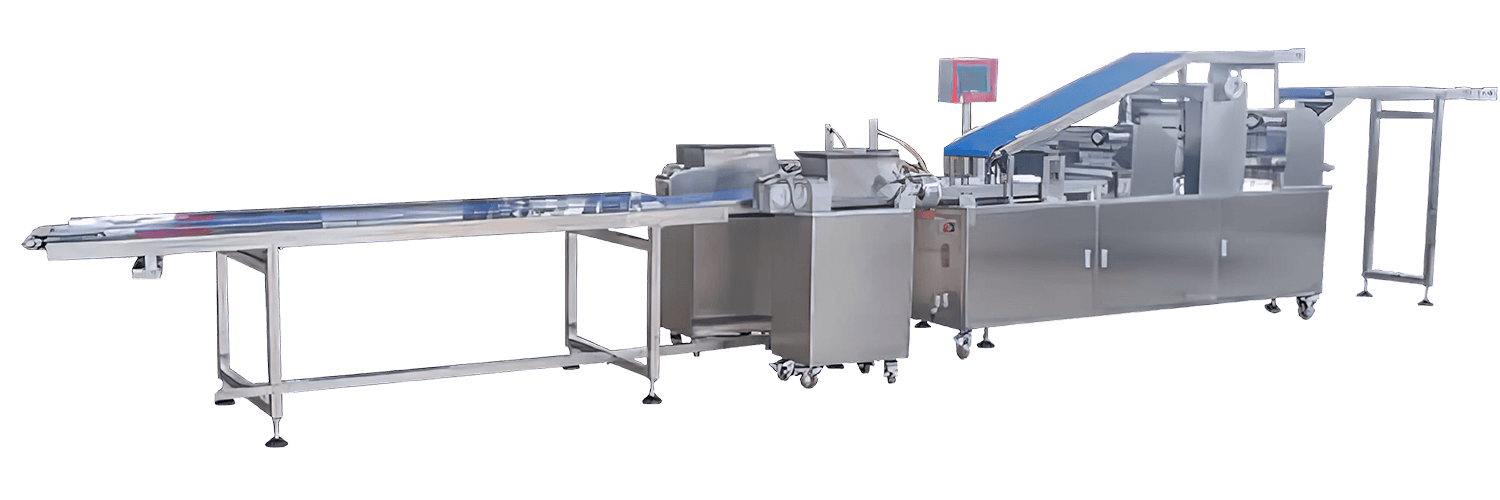

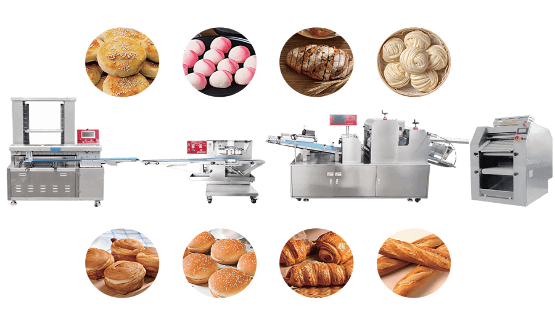

Hargao/Shrimp dumpling production line

-

2Automatic recycling device

It has an automatic recovery device to save labor.

-

3Easy cleaning

The body is made of stainless steel, and the hopper is easy to disassemble and clean.

-

4Easy adjustment

The thickness of skin and filling can be adjusted on the machine.

-

5Individual control

Each channel is controlled separately, which is easy to operate.

-

6High output

The leather maker is formed by a hob, one out of two, with high output.

Machine Brief Introduction

1. Three-stage progressive thinning method is adopted to press the skin into proper thickness

2. It has an automatic recovery device to save labor.

3. The body is made of stainless steel, and the hopper is easy to disassemble and clean.

4. The thickness of skin and filling can be adjusted on the machine.

5. Each channel is controlled separately, which is easy to operate.

6. The leather maker is formed by a hob, one out of two, with high output.

| Model | ST-340 Shrimp Dumplings Machine |

| Capacity | 420 meters per hour (m/h) |

| Product Weight | 15-25g/ Customised |

| Machine Dimension | Length (L) 9000 X Width (W) 1200 X Height (H) 1650 mm |

| Power | 2.5Kw 220v 50/60Hz |

| Machine Weight | 1100Kg |

We are production solution customization expert for food machinery,founded in 2010.

-

Automatic Bread Forming: Selecting the Right Machine for Your Line

Automatic Bread Forming: Selecting the Right Machine for Your LineAutomatic bread forming is most valuable when your operation needs consistent weight, shape, and throughput across long runs—without turning sanitation and changeover into the real bottlenecks. This a...

-

Small Size Automatic Encrusting Forming Machine: Practical Guide

Small Size Automatic Encrusting Forming Machine: Practical GuideWhat “Small Size” Should Mean for an Automatic Encrusting Forming Machine When buyers search for an automatic encrusting forming machine (small size), they usually need more than “compact.” In real p...

-

Dumpling Production: Scaling Output with Consistent Forming & Hygiene

Dumpling Production: Scaling Output with Consistent Forming & HygieneSet Practical Targets for Dumpling Production Before You Scale In commercial dumpling production, scaling successfully is less about “making more” and more about keeping key quality metrics stable wh...

English

English Español

Español Français

Français русский

русский عربى

عربى